Certified Insulation Systems for Enhanced Performance

External Wall Insulation (EWI) and façade systems, specifically designed for the construction market in Ireland.

Our certified systems offer a range of benefits, including flexible design choices, easy application, and superior durability. This makes them an excellent addition to our growing portfolio of accreditations. These accredited systems have been approved for use on various types of builds, whether you are working on New Build or Refurbishment projects. We are proud to offer you solutions that meet the highest standards and contribute to the success of your projects.

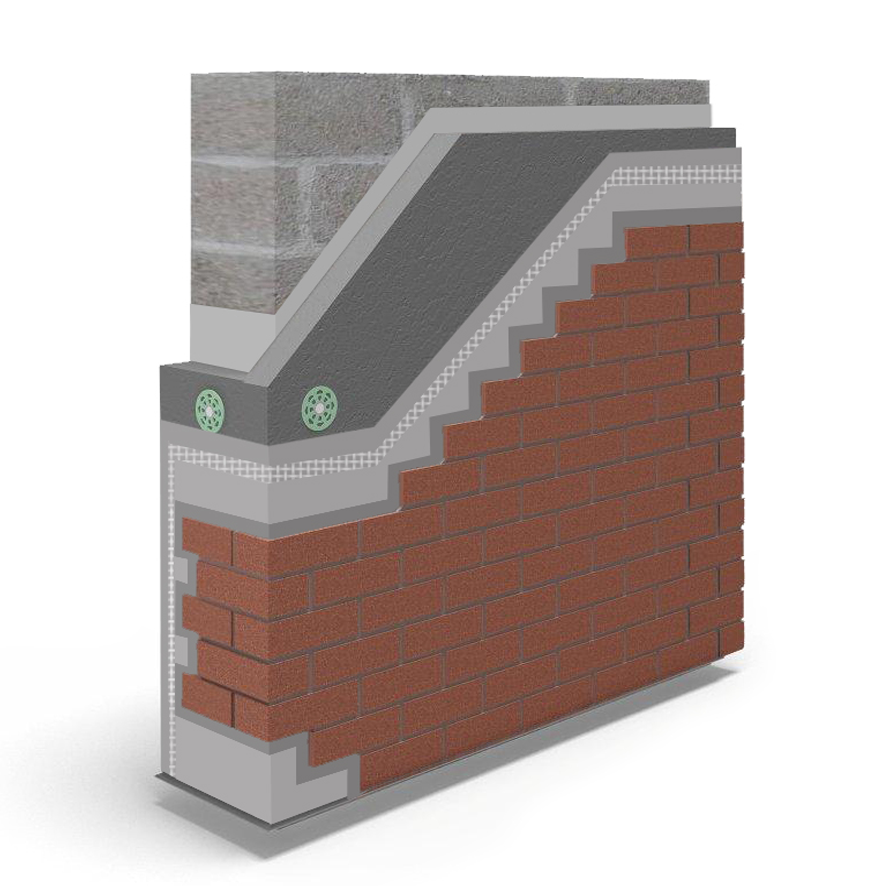

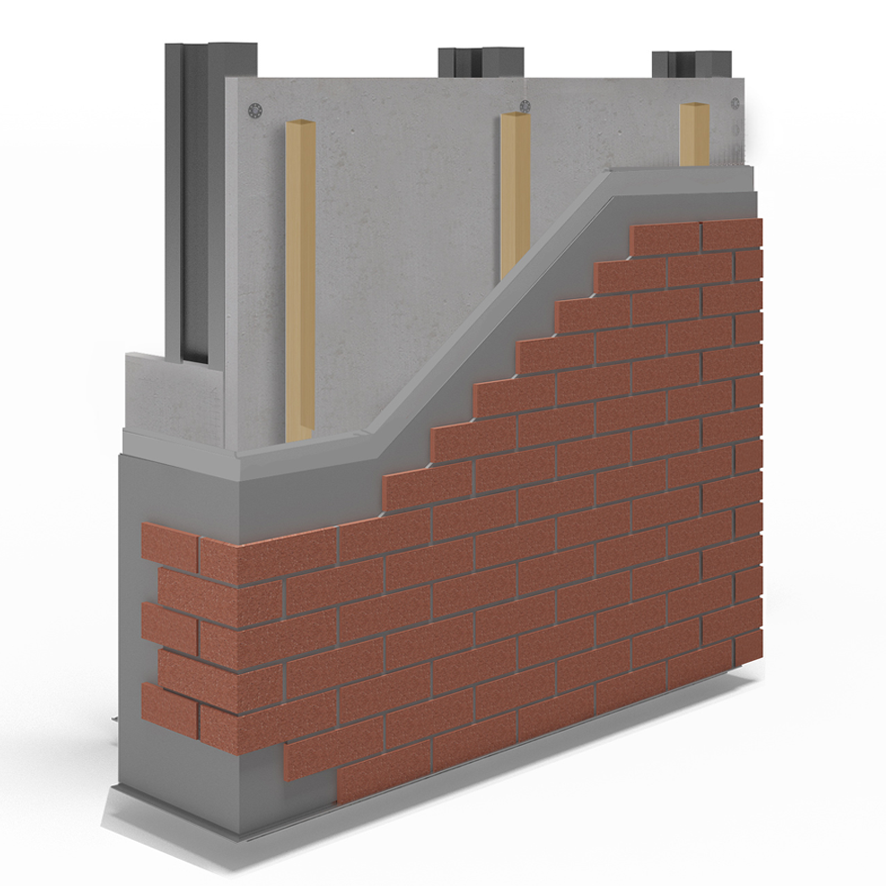

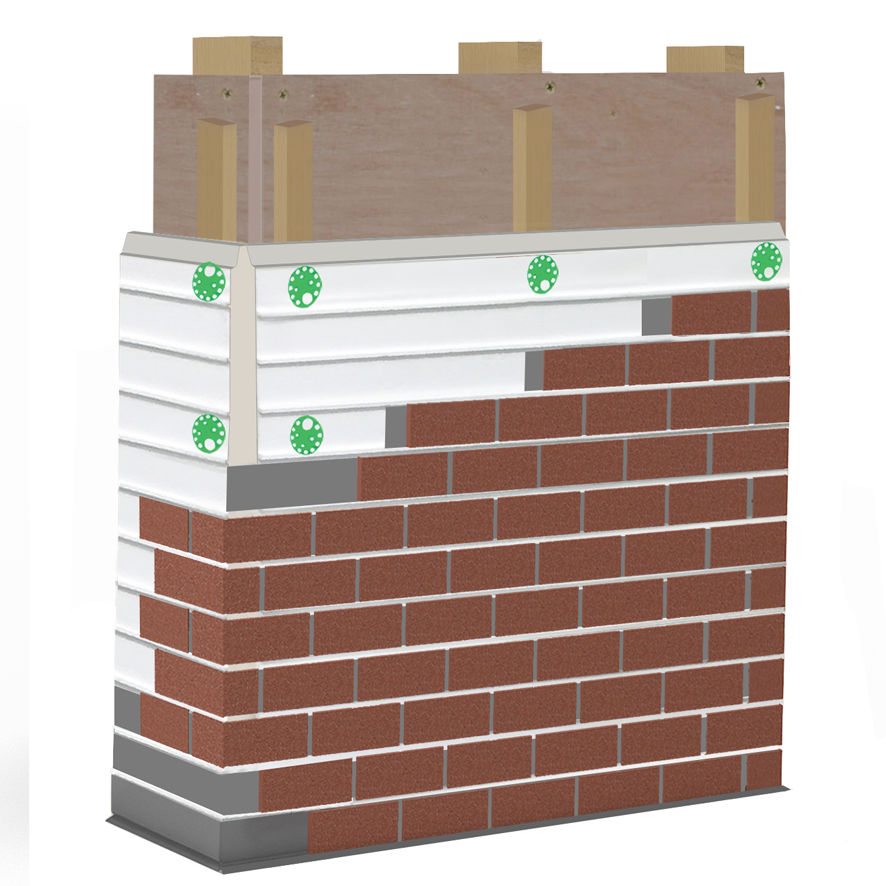

MASONRY SYSTEMS – Direct Fix Render and Brick Slip System

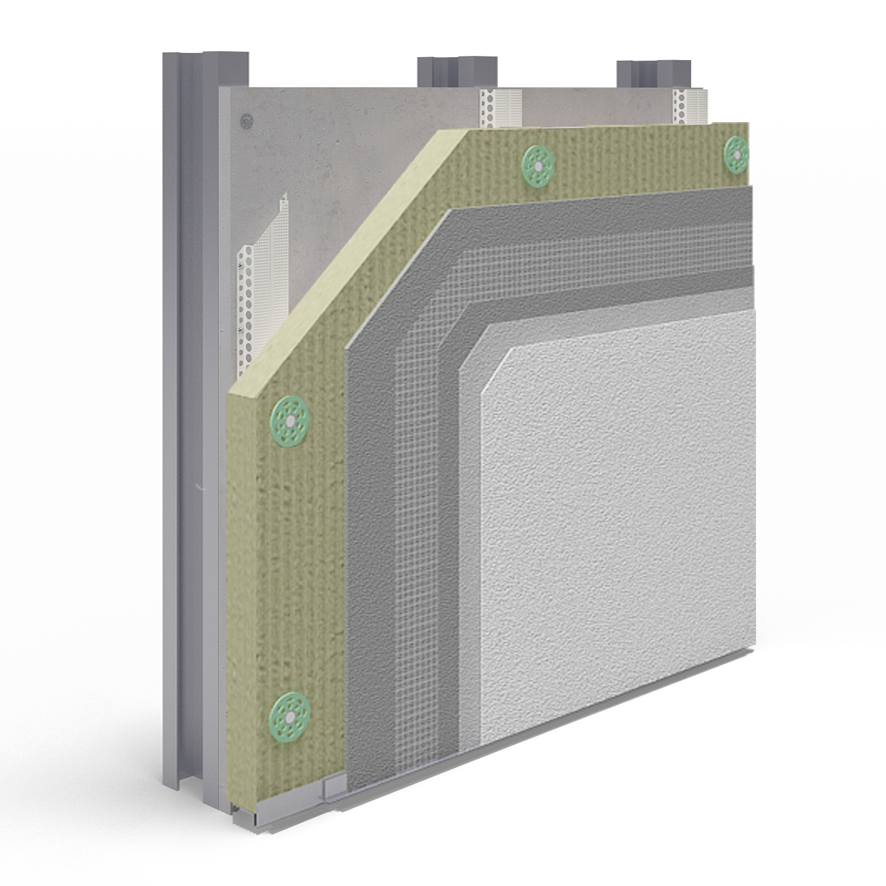

WBS STONE WOOL – MINERAL RENDER – A1

| Substrate: | Brick / Block / Concrete |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / K+A A1 Scrim Adhesive |

| Finish: | Heck Primer |

| Mineral Render & Silicone Paint |

WBS STONE WOOL – MINERAL RENDER – A1

| Substrate: | Brick / Block / Concrete |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / K+A Scrim Adhesive |

| Finish: | Heck Primer |

| Silicone Thin Coat Render |

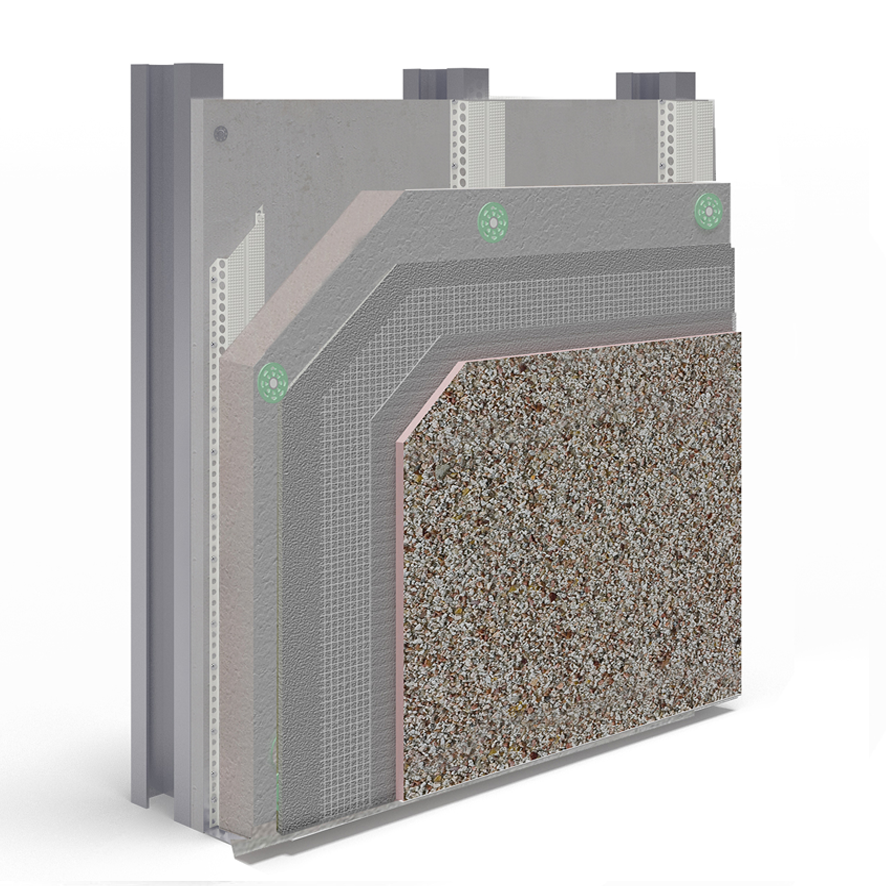

EPSICON – EWI – DASH – 30 & 60 YEARS

| Substrate: | Brick / Block / Concrete |

| Insulant: | Enhanced EPS / Phenolic / EPS |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Dash Receiver |

| Dry Dash Aggregate |

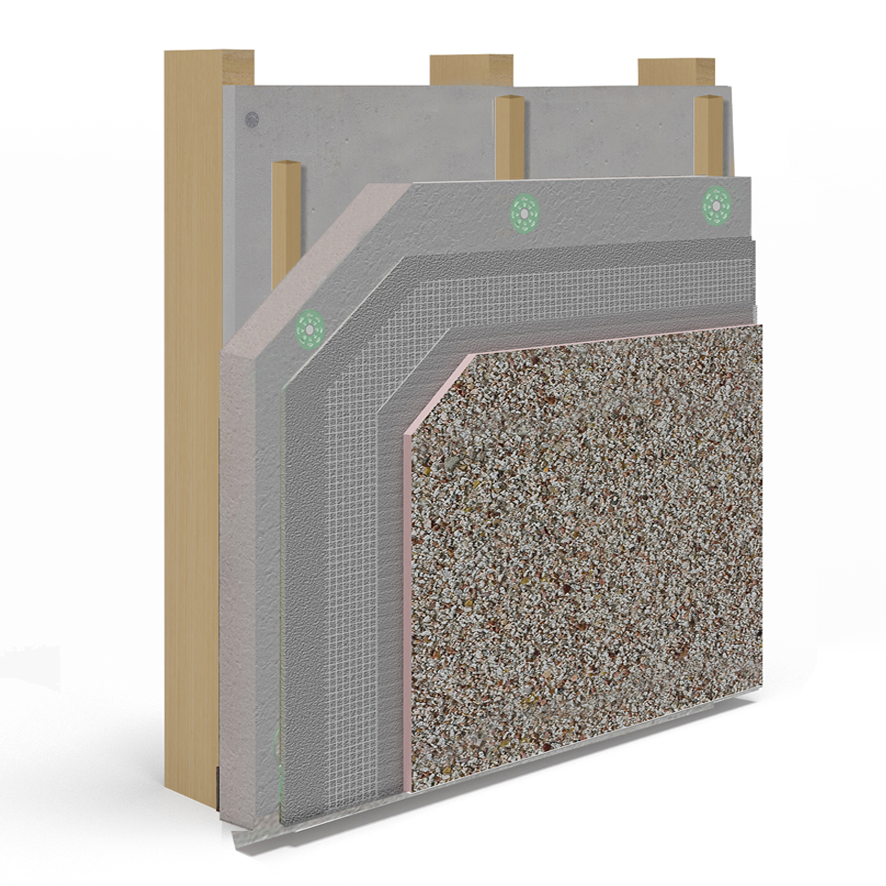

EPSICON – SW – DASH – 30 & 60 YEARS

| Substrate: | Brick / Block / Concrete |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Dash Receiver |

| Dry Dash Aggregate |

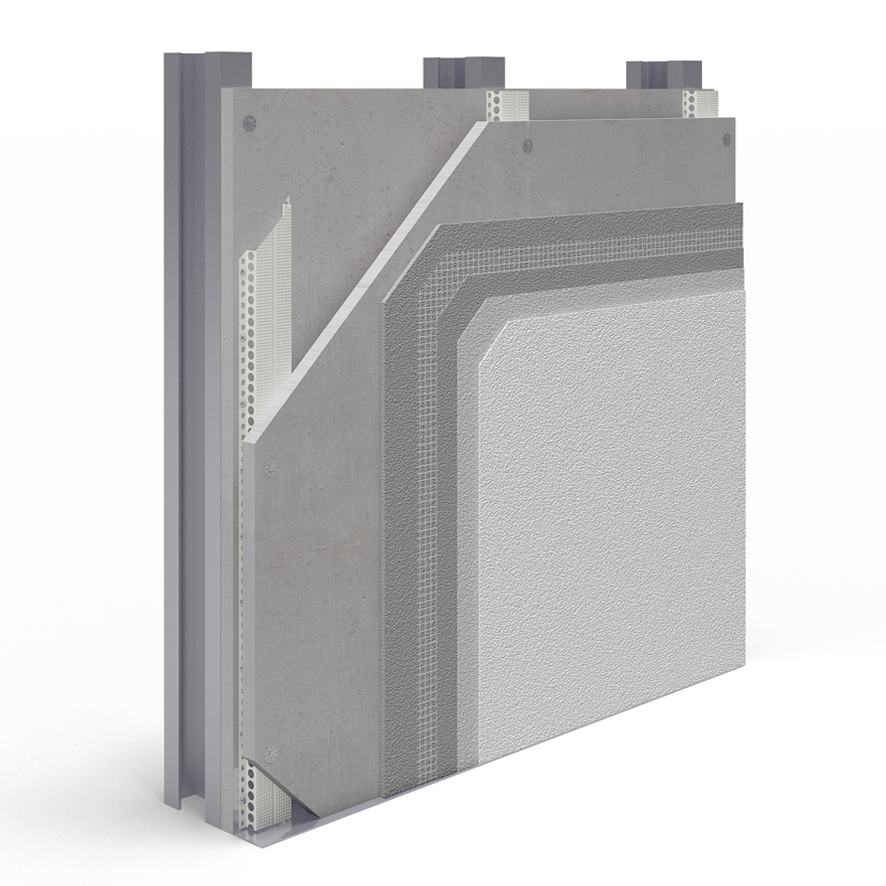

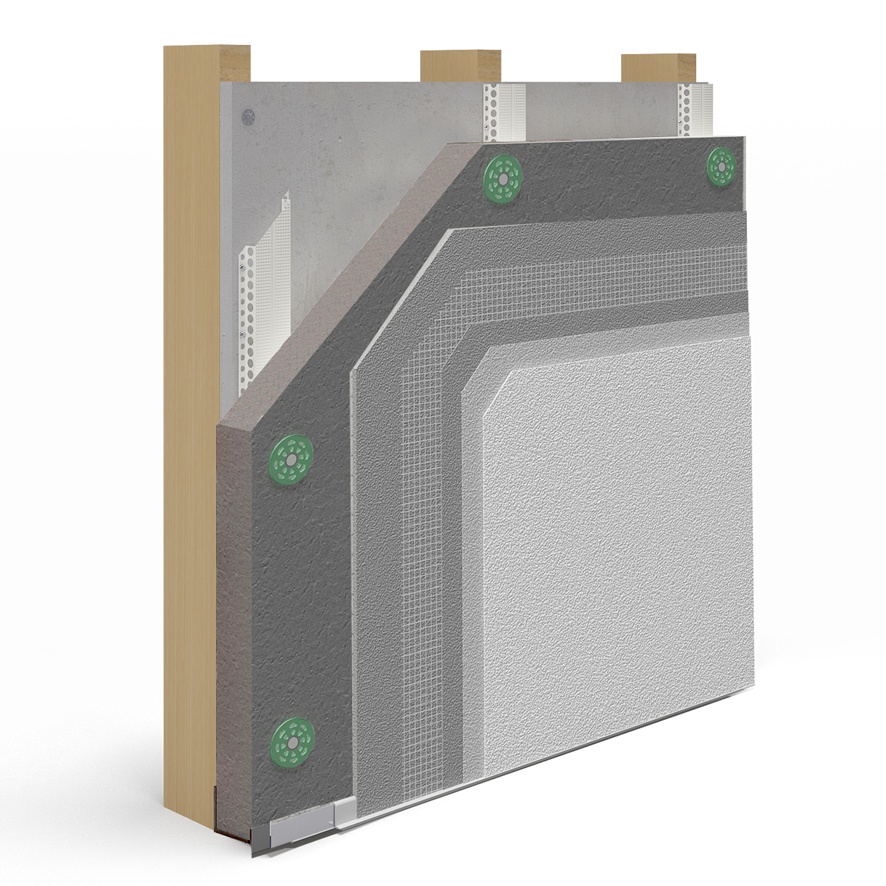

EPSIWALL – EWI – SILICONE – 30 & 60 YEARS

| Substrate: | Brick / Block / Concrete |

| Insulant: | Enhanced EPS/Phenolic |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

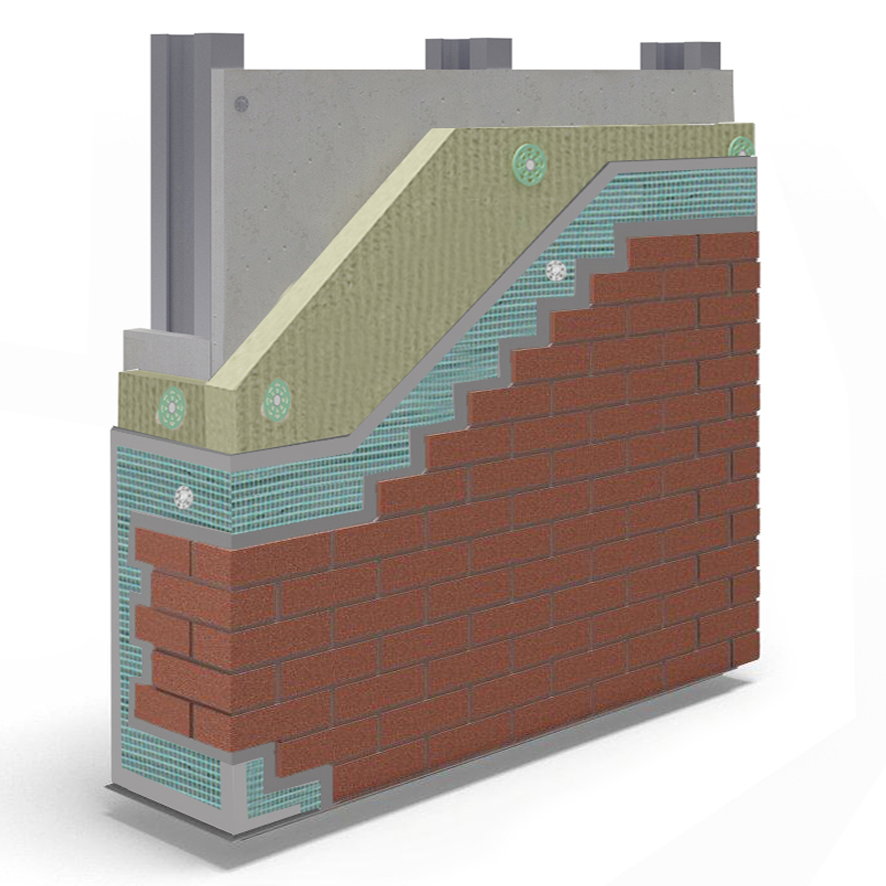

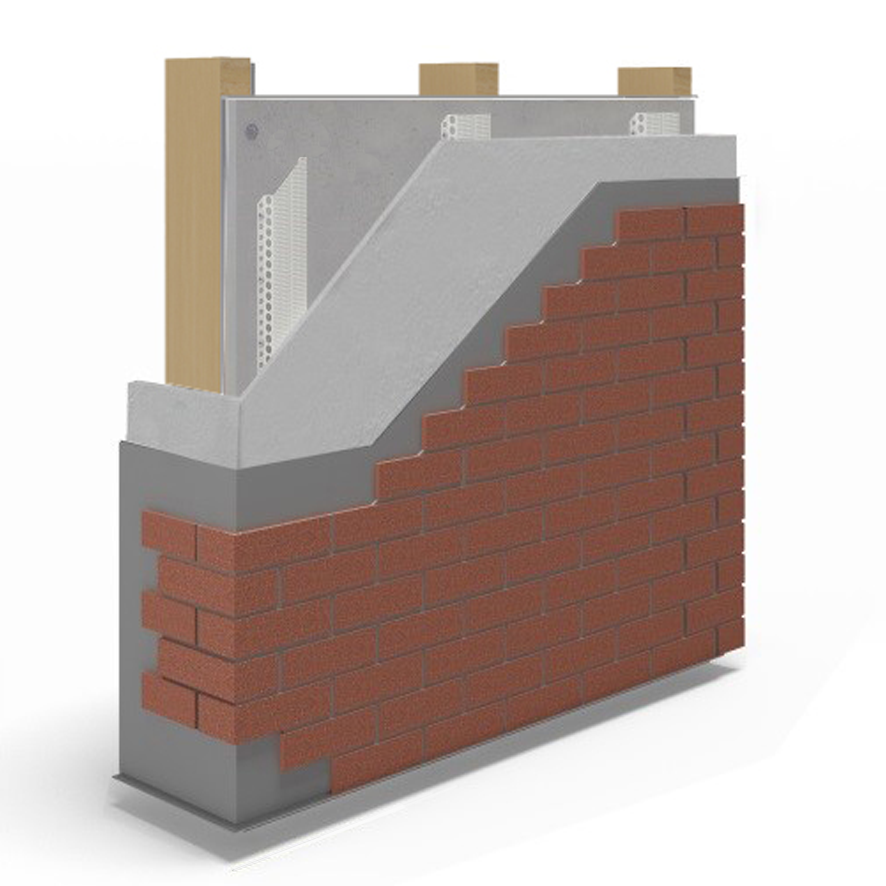

EPSIBRICK – EPS – BRICK SLIP

| Substrate: | Brick / Block / Concrete |

| Insulant: | Enhanced EPS |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Brick Slip Adhesive |

| Brick Slip 7-15mm | |

| Pointing Mortar |

EPSIBRICK – SW – BRICK SLIP

| Substrate: | Brick / Block / Concrete |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Brick Slip Adhesive |

| Brick Slip 7-15mm | |

| Pointing Mortar |

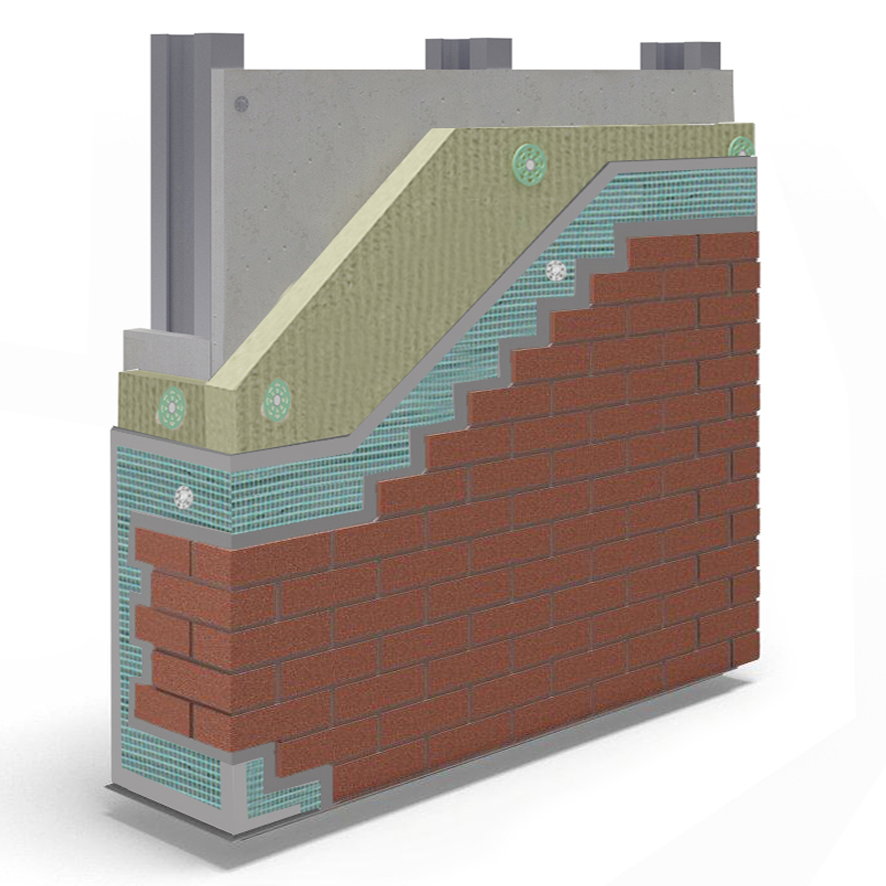

MASONRY – SW – ACRYLIC BRICK SLIP

| Substrate: | Brick / Block / Concrete |

| Adhesive | Insulation Adhesive |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Acrylic Brick Slip Adhesive |

| Acrylic Brick Slip |

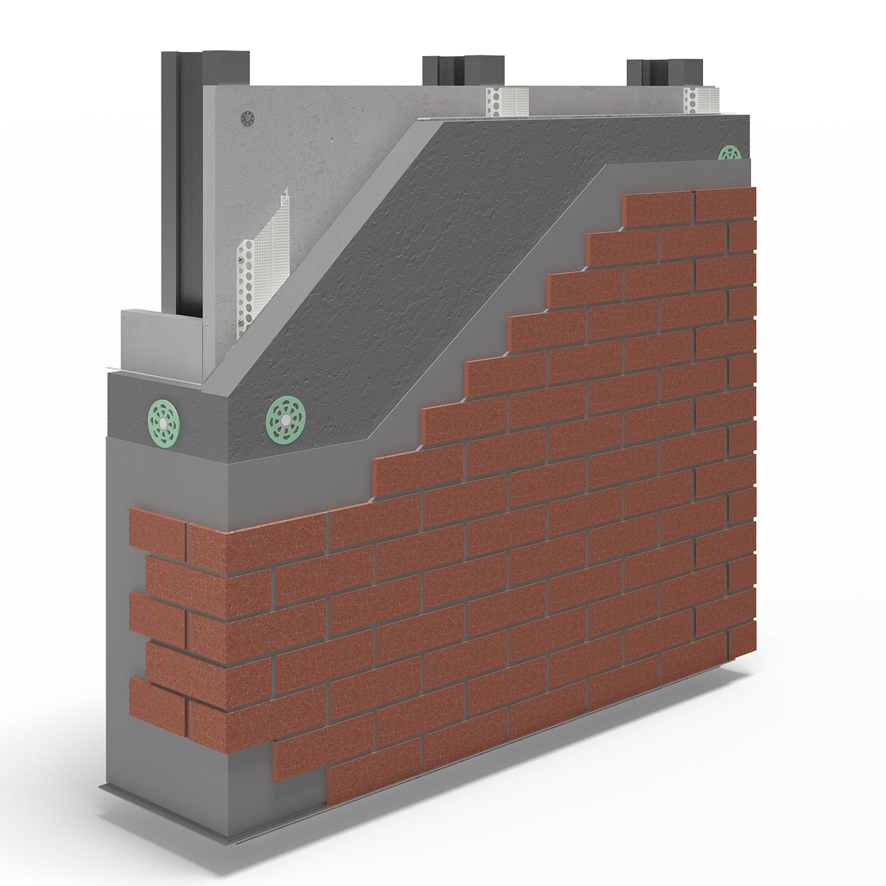

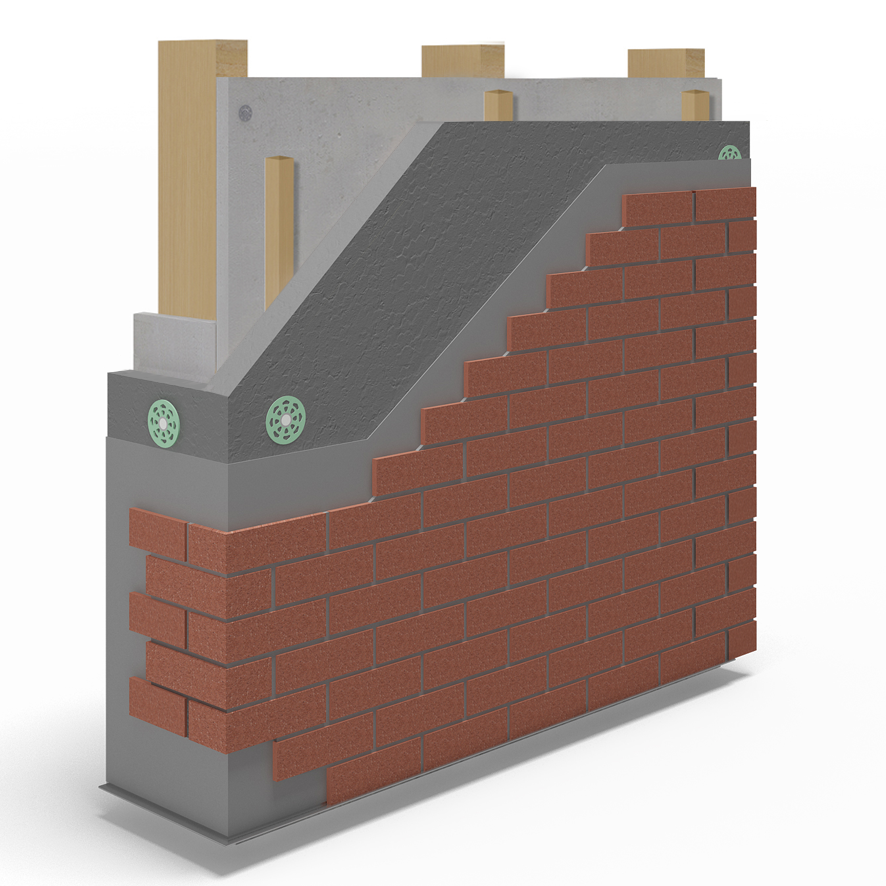

LIGHTWEIGHT STEEL FRAME & SFS INFILL SYSTEMS – Direct Fix Render and Brick Slip System – Not requiring a Structural Latent Defects Insurance

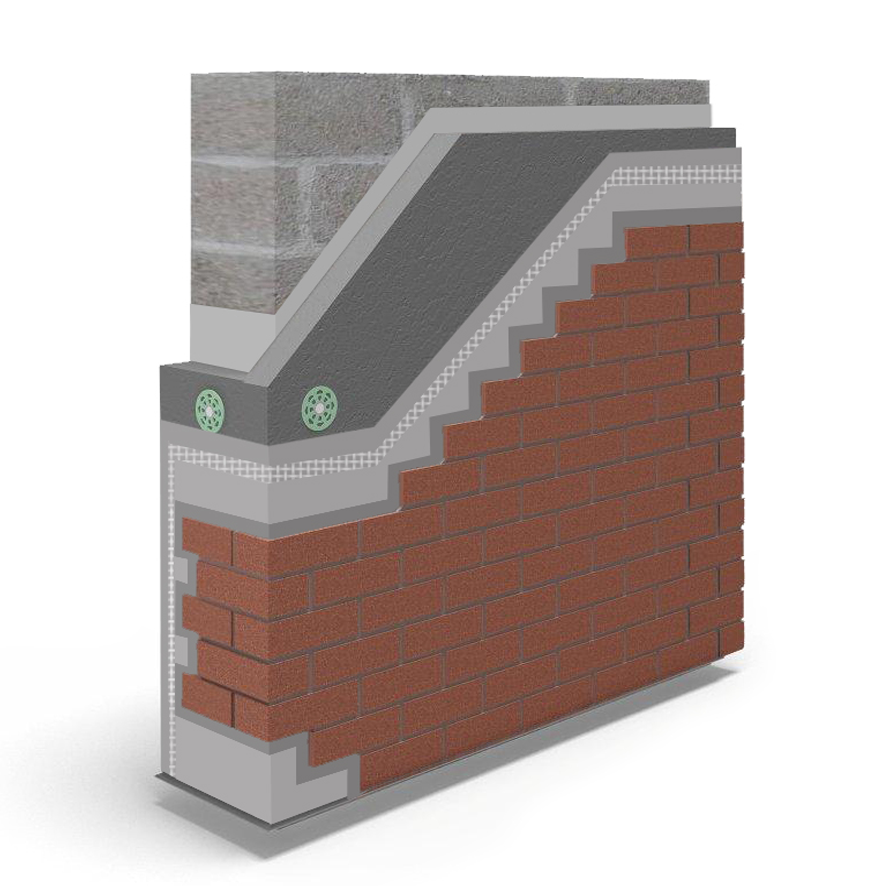

SFS – DIRECT FIX – SW – SILICONE

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Insulant: | Stone Wool |

| Reinforcement: | A1 Scrim / A1 Scrim Adhesive |

| Finish: | Primer |

| Mineral Render |

SFS – DIRECT FIX – SW – SILICONE

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

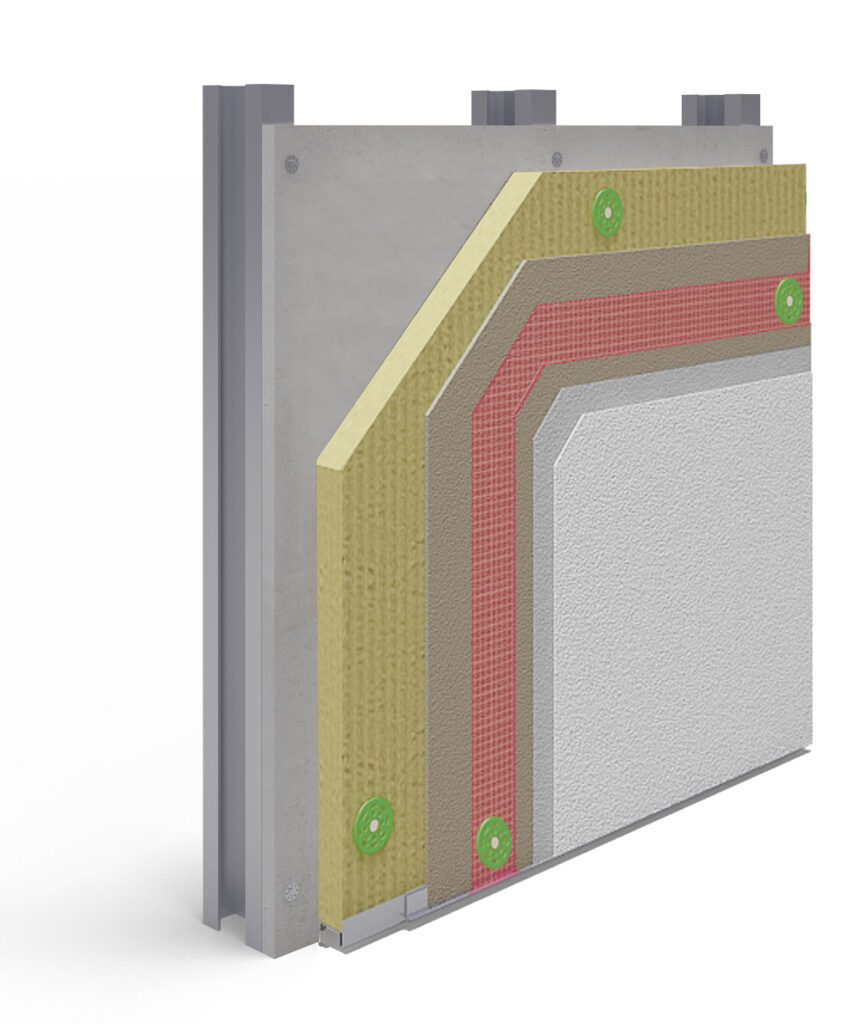

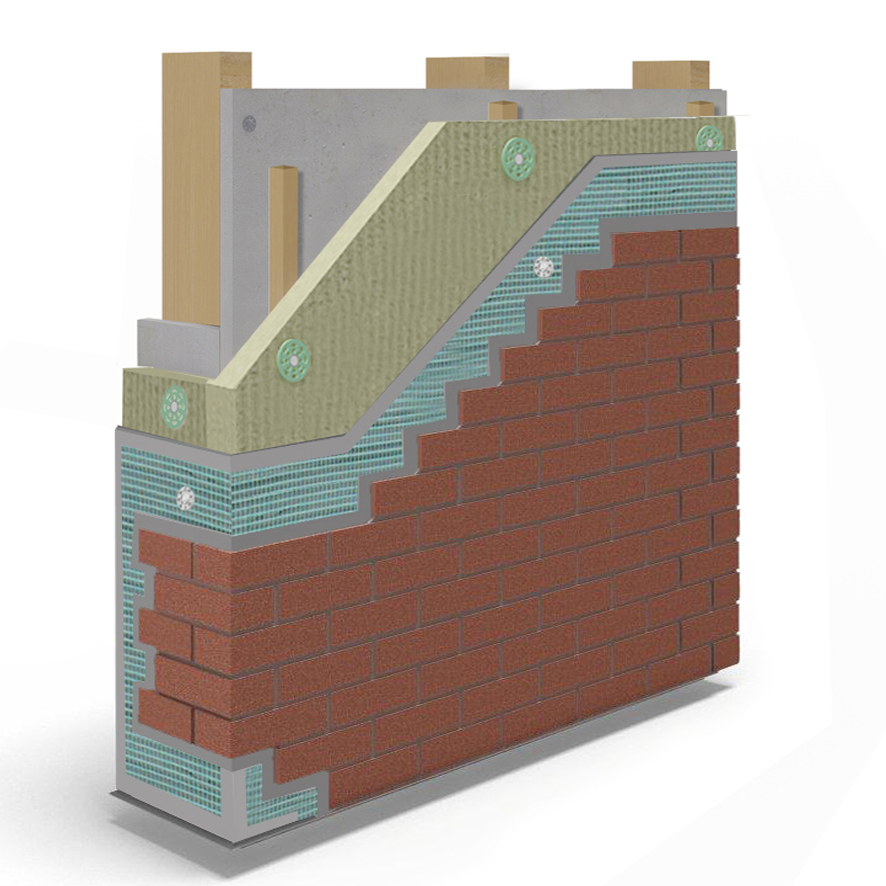

SFS – DIRECT FIX – SW – BRICK SLIP

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Brick Slip Adhesive |

| Brick Slip 9-15mm | |

| Pointing Mortar |

SFS – DIRECT FIX – SW – ACRYLIC BRICK SLIP

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Acrylic Brick Slip Adhesive |

| Acrylic Brick Slips |

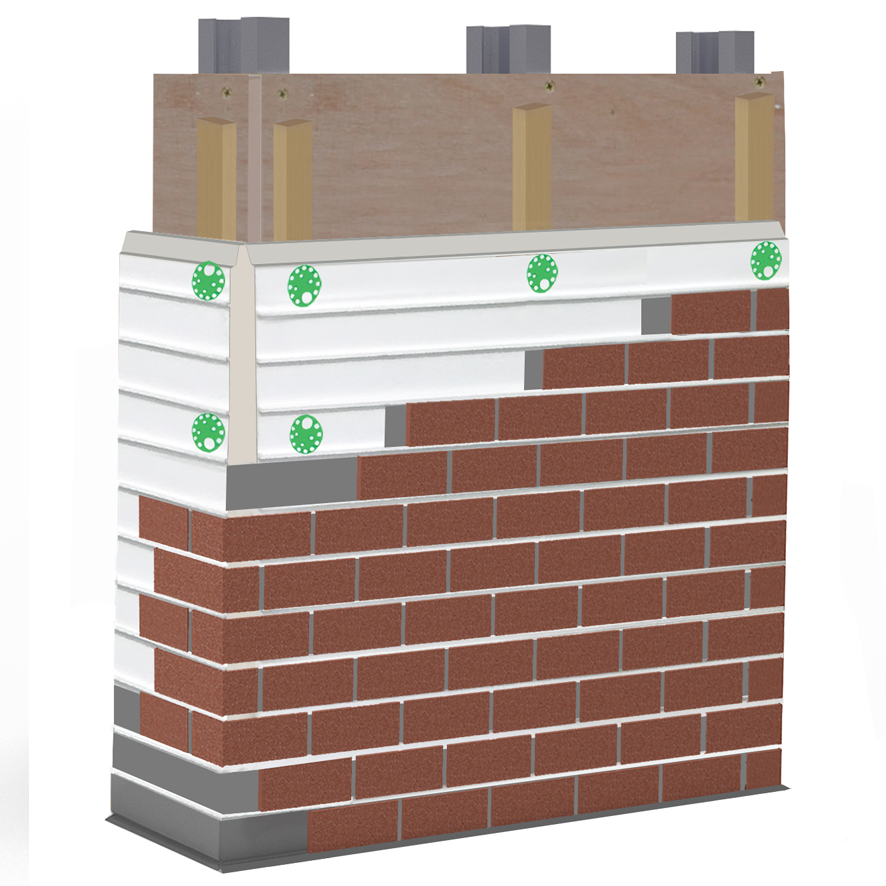

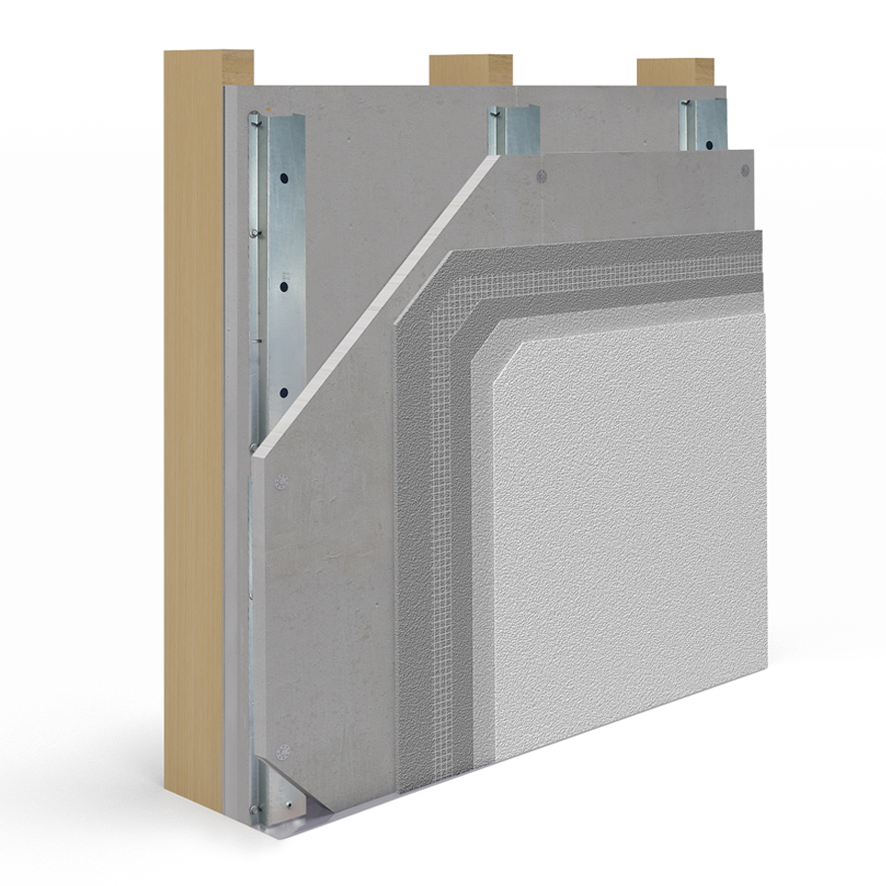

LIGHTWEIGHT STEEL FRAME & SFS INFILL SYSTEMS – Drained Cavity Rail System – Render and Brick Slip

EPSITEC SFS – EWI – SILICONE

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS / Phenolic |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

EPSITEC SFS – SW – SILICONE

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

EPSITEC SFS – EPS – DASH

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS / Phenolic |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Dash Receiver |

| Dry Dash Aggregate |

EPSITEC SFS – RCB – SILICONE

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Secondary Board: | Render Carrier Board |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Finish |

EPSITEC SFS – RCB – BRICK SLIP

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Secondary Board: | Render Carrier Board |

| Reinforcement: | Brick Slip Adhesive |

| Finish: | Brick Slip 7-15mm |

| Pointing Mortar |

SFS MODULAR SYSTEM 1 – HD EPS – BRICK SLIP

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant | High Density Grooved EPS |

| Reinforcement: | Brick Slip Adhesive |

| Finish: | Brick Slip 9-15mm |

| Pointing Mortar |

SFS MODULAR SYSTEM 2 – EPS – BRICK SLIP

| Substrate: | Steel Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant | Enhanced EPS |

| Reinforcement: | Brick Slip Adhesive |

| Finish: | Brick Slip 9-15mm |

| Pointing Mortar |

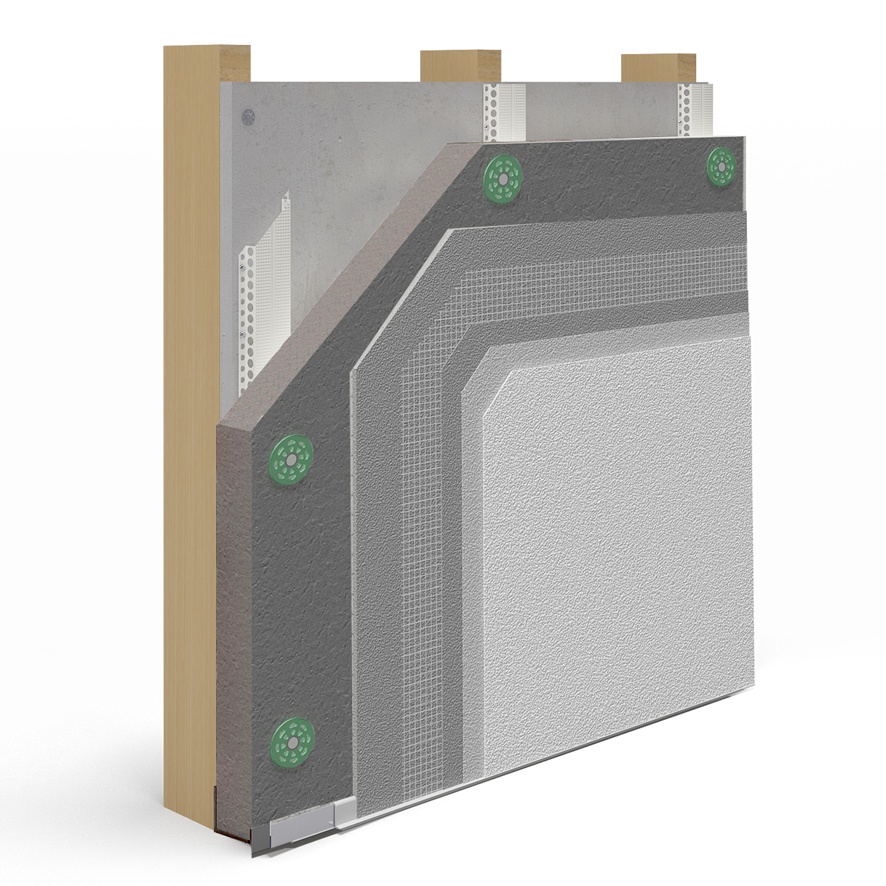

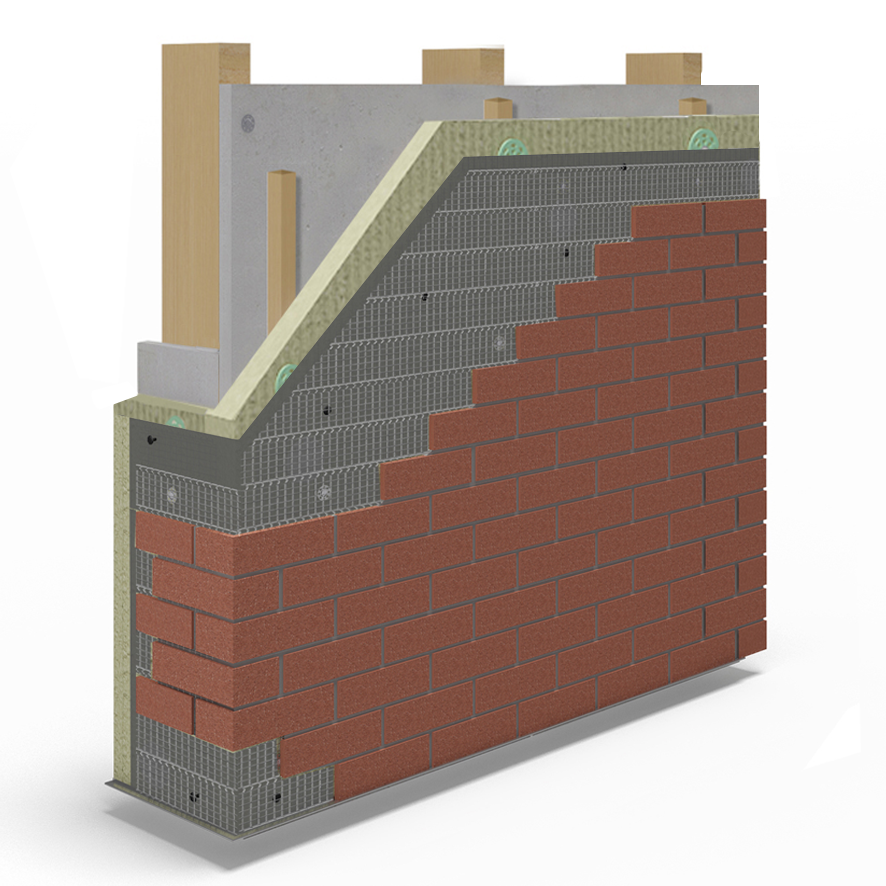

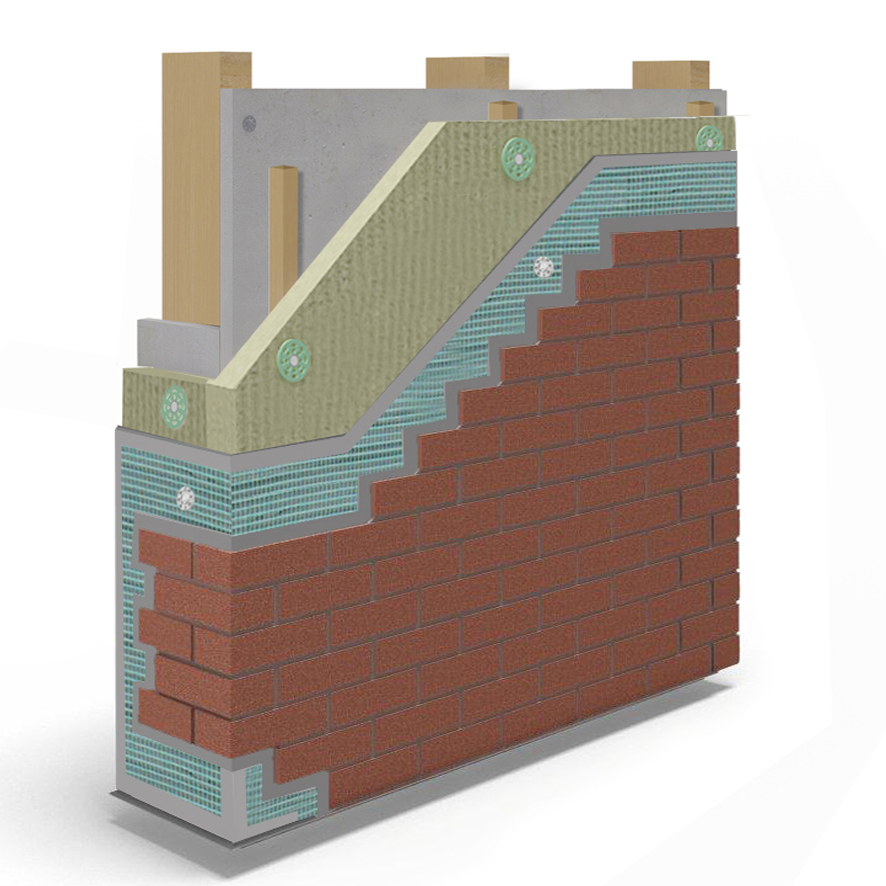

TIMBER FRAME SYSTEMS – Drained Cavity Rail System – Render and Brick Slip System

EPSITEC TIMBER FRAME –EPS– SILICONE

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS / Phenolic |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

EPSITEC TIMBER FRAME – SW – SILICONE

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS / Phenolic |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

EPSITEC TIMBER FRAME – EPS – DASH

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Dash Receiver |

| Dry Dash Aggregate |

EPSITEC TIMBER FRAME – RCB –SILICONE

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Primer |

| Silicone Thin Coat Render |

EPSITEC TIMBER FRAME – RCB – BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Secondary Board: | Render Carrier Board |

| Reinforcement: | Brick Slip Adhesive |

| Finish: | Brick Slip 7-15mm |

| Pointing Mortar |

TF MODULAR SYSTEM 1 – HD EPS – BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | High Density Grooved EPS |

| Adhesive: | Brick Slip Adhesive |

| Finish: | Brick Slip 7-15mm |

| Pointing Mortar |

TF MODULAR SYSTEM 2 – EPS – BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Enhanced EPS |

| Reinforcement: | Scrim / Scrim Adhesive |

| Finish: | Brick Slip 7-15mm |

| Pointing Mortar |

TF MODULAR SYSTEM 3 – SW – MESH – BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive / Profiled Brick Mesh |

| Finish: | Brick Slip 9-15mm |

| Pointing Mortar |

TF – CAVITY RAIL – SW – SCRIM/PIN – CLAY BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| 2nd Fix Through Mesh | |

| Adhesive: | Clay Brick Slip Adhesive |

| Finish: | Clay Brick Slip 9-15mm |

| Pointing Mortar |

TF – CAVITY RAIL – SW – SCRIM/PIN – ACRYLIC BRICK SLIP

| Substrate: | Timber Frame |

| Sheathing Board | CPB/OSB/PLY |

| Drainage Cavity | Epsitec Rail / Timber Batten |

| Insulant: | Stone Wool |

| Reinforcement: | Scrim / Scrim Adhesive |

| 2nd Fix Through Mesh | |

| Adhesive: | Clay Brick Slip Adhesive |

| Finish: | Acrylic Brick Slip Adhesive |

| Acrylic Brick Slips |

Contact Us

Contact our Technical Sales Manager below for more information on our certified Brick Slip and Render systems for the Republic of Ireland. Alternatively, you can contact us via the enquiry form below.

Email Technical Sales ManagerFAQ’S

Why do you have two options for the same substrate ?

If the project requires a Latent Structural Defects Insurance such as HomeBond then they stipulate that a Drained Cavity System is required for Light Gauge Steel Frame and SFS Infill, if the project doesn’t require any Latent Structural Defects Insurance then the Direct Fix System can be used.

What Euroclass Fire Rating is achieved with Option 1 or Option 2 are they Non-Combustible ?

The Render System is tested to EN 13501-1 and has a Euroclass A2 Fire Rating and is fully Non-Combustible and if you used our 15mm or 20mm Clay Brick Slip System that has been tested to EN 13501-1 this has a Euroclass A1 Fire Rating and is fully Non-Combustible

Is there any Height Restrictions for the Direct Fix or Drained Cavity Rail System ?

Both systems have been Certified and Tested with no Height Restrictions

Do you have any Certification in Ireland to comply with Building Regulations and the latest European Standards ?

Yes we have Full Certification for the Direct Fix System finished with either a Render or Brick Slip Finish, and for the Drained Cavity Rail System we currently have Full Certification for the Clay Brick Slip System with amendments currently in progress for the Render System to be updated within the next 4-6 weeks.

Is the Certification an NSIA Cert ?

An NSIA Certification isn’t a mandatory requirement in the Republic of Ireland, the latest Building Regulation Documents stipulate that any proposed Product or System must have one of the following to achieve compliance.

Technical Specifications Building Regulations are made for specific purposes, e.g. to provide, in relation to buildings, for the health, safety and welfare of persons, the conservation of energy and access for people with disabilities. Technical specifications (including harmonised European Standards, European Technical Assessments, National Standards and Agrément Certificates) are relevant to the extent that they relate to these considerations

Both our systems have a National Standards and Agrément Certification plus all our product components meet the Harmonised European Standards.

What thickness of External Insulation is required to meet a 0.18 U-Value using your Systems ?

As an example based on a 100mm SFS Stud fully filled with Rockwool RWA45 Insulation you’d need 110mm External Insulation to meet a 0.18 U-value.

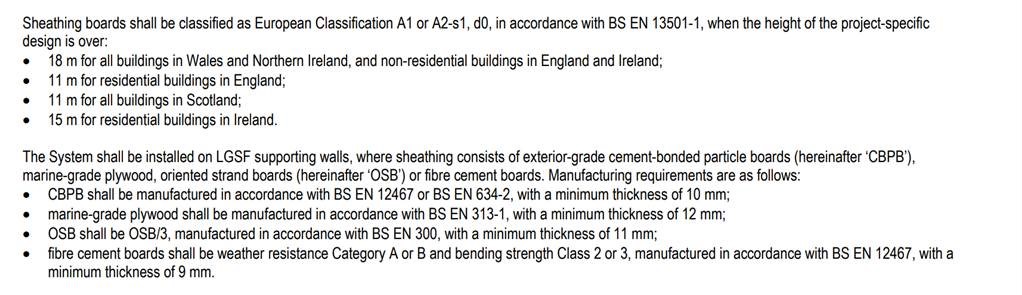

Is there a specific Sheathing Board required to fall in line with your Certification and Testing ?

As an example based on a 100mm SFS Stud fully filled with Rockwool RWA45 Insulation you’d need 110mm External Insulation to meet a 0.18 U-value.

01942 717 100

01942 717 100

01942 717 100

01942 717 100