Brick Slip Cladding

Wetherby are experts in brick slip cladding systems. We offer a wide range of brick slips, available in an array of colours and textures for external and internal use.

What are Brick Slips?

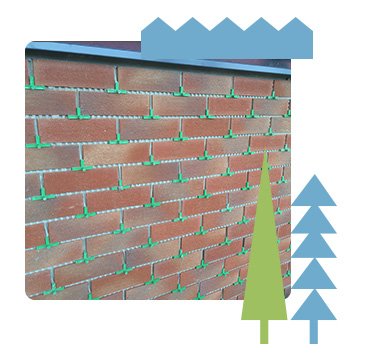

Brick is familiar, comforting and reliable. That is why it is still a popular choice of finish for architects seeking to incorporate the traditional values of warmth and strength in their designs. Traditionally, brick slips were manufactured by literally removing the face of an existing brick. This however proved to be very costly and led to a substantial amount of waste material. Wetherby Brick Slips provide a unique, cost effective method of achieving a genuine brick effect by using brick slips and pistol corners that have been specially designed for this particular purpose. The Wetherby Brick Slip Systems are particularly beneficial, especially for projects where the use of real brick is impossible or impractical.

Brick Slip Benefits

- Offer a professional, real brick finish

- Give a higher level of accuracy and alignment

- Superb adhesion properties

- Faster application compared to traditional methods

- Additional foundations are not required

- Suitable for both internal and external applications

Unlike other brick slip systems currently available, which often comprise of an acrylic brick finish, Wetherby brick slips are manufactured and fired at a 7mm thickness, in exactly the same way as traditional clay bricks.

The Wetherby Brick Slip System provides a unique, cost effective method of achieving a genuine brick effect by using brick slips, especially where the use of real brick is impractical. Traditionally, brick slips were manufactured by literally removing the face of an existing brick. This however proved very costly and led to a substantial amount of waste material.

01942 717 100

01942 717 100

01942 717 100

01942 717 100